The relentless march of automation is transforming manufacturing floors at an unprecedented pace. Gone are the days of purely manual operations, where human hands were the primary drivers of production. Today, the scenario has shifted dramatically, and a symphony of interconnected machines and devices orchestrates production with remarkable efficiency and precision. Each piece of machinery communicates seamlessly with the other, creating a harmonious industrial ballet. This sophisticated dance of technology, however, necessitates a reliable conductor—a robust network infrastructure that can handle the ever-growing demands of data exchange and communication.

Enter Industrial PoE (Power over Ethernet) Switches, the unsung heroes powering the next generation of factory automation. These advanced switches are not merely static pieces of technology; they are dynamic enablers of progress. They ensure that every machine, sensor, and device on the factory floor is connected and powered efficiently, facilitating an uninterrupted flow of information. This capability is crucial for maintaining the high levels of productivity and quality control required in modern manufacturing environments. Without Industrial PoE Switches, the intricate network of production would falter, and the seamless efficiency we have come to expect would be compromised.

The Struggles of the Traditional Network

Before diving into the world of PoE switches, let’s consider the limitations of traditional factory networks. These setups often rely on a web of separate power cables for each device, creating a tangled mess and hindering scalability. Additionally, non-managed switches, while cost-effective, lack features like traffic prioritization and advanced security, potentially leading to network bottlenecks and vulnerabilities.

Industrial PoE Switches: Powering Up Efficiency

Industrial PoE switches come to the rescue, offering a potent blend of power delivery and intelligent network management. Here’s what makes them shine:

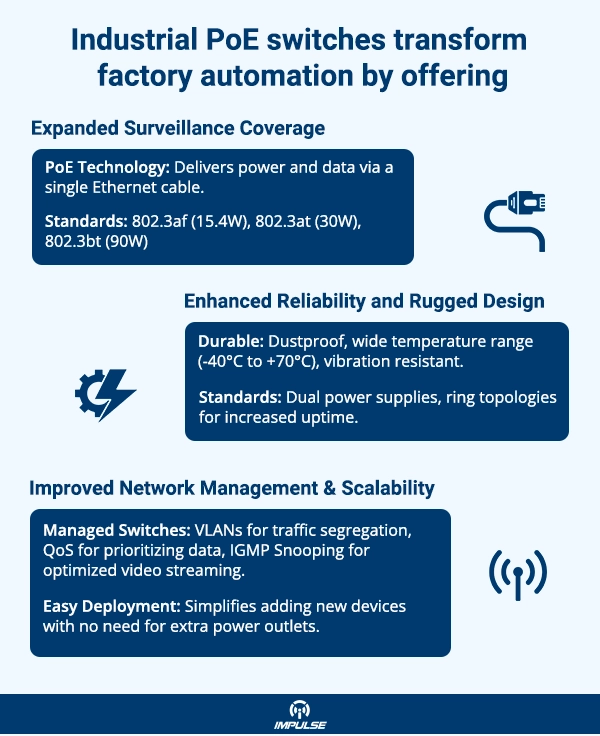

- Power Delivery and Simplified Cabling: Power over Ethernet (PoE) technology eliminates the need for separate power cables. The switch itself delivers power to compliant devices using the same Ethernet cable that transmits data. This translates to cleaner installations, reduced cabling costs, and easier device deployment. Different PoE standards exist, with 802.3af providing up to 15.4 watts, 802.3at (PoE+) reaching 30 watts, and the latest 802.3bt (PoE++) delivering a whopping 90 watts. This allows powering a wider range of devices, including high-resolution IP cameras and advanced sensors.

- Enhanced Reliability and Rugged Design: Industrial PoE switches are built to withstand the harsh realities of factory floors. Dustproof enclosures, wider operating temperature ranges (-40°C to +70°C), and vibration resistance ensure uninterrupted operation in demanding environments. Redundancy features like dual power supplies and ring topologies further enhance network uptime, minimizing production downtime.

- Improved Network Management and Scalability: Managed PoE switches provide granular control over your network. Features like VLANs (Virtual LANs) segregate traffic for different applications, ensuring smooth operation of critical systems. Quality of Service (QoS) prioritizes time-sensitive data like machine control, while IGMP Snooping optimizes video streaming for IP cameras. Adding new devices becomes a breeze with PoE, eliminating the need for additional power outlets.

Also Read: POE vs. Non-POE Switches: What’s the Difference?

Powering the Devices of Automation

The benefits of Industrial PoE switches extend far beyond simplified cabling. These switches not only reduce the complexity of wiring but also offer increased flexibility and scalability for industrial environments. Here are some key players in the world of factory automation that leverage PoE technology:

- IP Cameras: Keep a watchful eye on production lines and ensure security with PoE-powered IP cameras. These cameras deliver high-resolution video streams for real-time monitoring and process analysis. Enhanced with advanced features like night vision and motion detection, these cameras are crucial for maintaining a secure and efficient production environment.

- Wireless Access Points: Empower workers with mobile devices by deploying PoE-powered wireless access points. This enables real-time data access, remote equipment control, and improved collaboration on the factory floor. The flexibility of wireless connectivity ensures seamless communication and operational efficiency across various departments.

- VoIP Phones: Facilitate clear and reliable communication with PoE-powered VoIP phones. This allows for efficient coordination between teams and improved response times to production issues. With features such as call forwarding, conferencing, and voicemail, these devices enhance internal communication and ensure that critical information is relayed promptly.

- Sensors and Actuators: The backbone of data collection and control, Power over Ethernet (PoE)powered sensors gather critical production data, while actuators perform automated tasks based on real-time information. These devices are essential for implementing advanced automation strategies like predictive maintenance and closed-loop control. By continuously monitoring various parameters and executing precise actions, they help optimize production processes, reduce downtime, and increase overall productivity.

Securing the Powerhouse

With the rapid advancement and increased connectivity in technology, the need for robust security measures has never been more critical. While Power over Ethernet (PoE) networks offer significant advantages, they aren’t immune to potential threats, such as unauthorized access or sophisticated cyberattacks. Managed PoE switches provide an extensive array of security features to mitigate these risks, including user authentication, access control lists (ACLs), and secure communication protocols like SSH and HTTPS. Moreover, implementing best practices such as creating strong, complex passwords, performing regular firmware updates, and conducting periodic security audits helps in maintaining a secure network environment. Adopting these measures ensures that the network remains resilient against evolving threats and continues to operate efficiently and securely

Also Read: The Future of PoE Networking: What’s Next for this Growing Market?

The Future is PoE-Powered

Industrial PoE Switches are not just making waves but are revolutionizing factory automation by streamlining deployments, enhancing reliability, and enabling more efficient network management. As Industry 4.0 unfolds, with its emphasis on intelligent manufacturing and interconnected systems, the role of PoE will only become more prominent, creating new opportunities for innovation. These switches simplify the setup process by reducing the need for separate power and data cables, which can significantly cut down on installation time and costs. With the ability to power and manage a wider range of devices, PoE switches are poised to become the cornerstone of the smart factory of the future. Furthermore, as more devices become interconnected, the need for robust and reliable network infrastructure will grow, and PoE switches will be at the heart of this transformation, ensuring seamless communication and operation within the smart factory ecosystem.

Conclusion

In the ever-evolving landscape of factory automation, Industrial PoE Switches are pivotal components driving efficiency, connectivity, and reliability. These switches offer numerous benefits, including simplified cabling, power delivery, enhanced network management, and security. By integrating PoE technology, factories can overcome traditional networking limitations and pave the way for advanced automation solutions. They facilitate a more agile and responsive manufacturing environment, capable of adapting to the dynamic demands of modern production processes.

The impact of Industrial PoE Switches extends beyond technical advantages. They enable a more interconnected and intelligent factory floor, powering and managing devices like IP cameras, wireless access points, VoIP phones, and sensors. Emphasizing security within PoE networks ensures factories remain protected against potential threats. As Industry 4.0 unfolds, PoE technology will be at the forefront of innovation, driving productivity and opening new avenues for technological advancement. Embracing Industrial PoE Switches future-proofs factory automation infrastructure, positioning manufacturers to capitalize on a more connected, efficient, and secure production environment.

Explore Impulse CCTV’s range of reliable and advanced NVR solutions. Visit our website today to learn more and find the perfect NVR system to meet your security needs.